Call Us:

0161 477 0775

Call Us:

0161 477 0775

When it comes to efficient and precise metal shaping, roll forming machines are one of the most valuable tools in the industrial and manufacturing sectors. At Bulldog UK, we offer a comprehensive range of roll formers that are designed to handle complex metal forming tasks with accuracy and speed. In this article, we will explore the power of roll formers, their benefits, and the various machines we provide to help you take your production capabilities to the next level.

Visit our Roll Forming Machines page to explore our full range of machines and solutions.

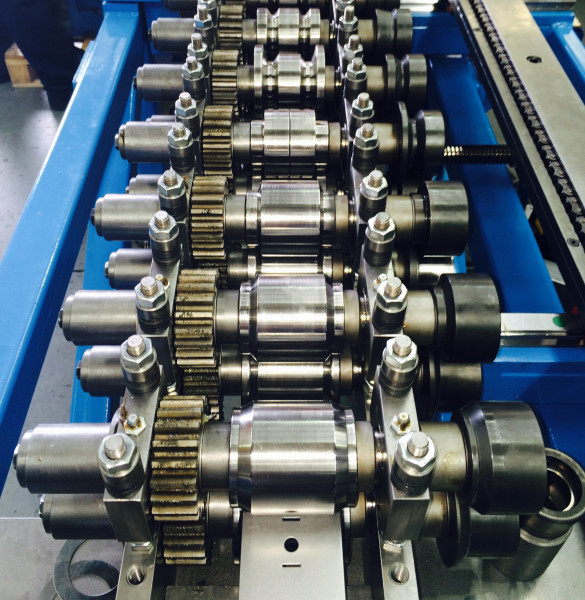

Roll forming is a continuous metal forming process in which a long strip of metal, usually coiled steel, is passed through a series of rolls that progressively shape the metal into the desired profile. This method is ideal for producing large quantities of uniform metal sections, which are commonly used in industries such as construction, automotive, and appliance manufacturing.

The process is highly efficient, allowing manufacturers to produce complex shapes with tight tolerances and minimal waste, making it a cost-effective solution for high-volume production runs.

Roll forming machines offer unparalleled precision, ensuring that each metal profile is formed with exact measurements. This level of accuracy is crucial for industries where components must meet strict specifications, such as construction materials like roofing panels, metal beams, and cladding.

One of the greatest advantages of roll formers is their ability to produce large quantities of metal parts quickly. Once set up, these machines can run continuously, significantly reducing production time and increasing overall output. This makes roll forming the go-to solution for manufacturers seeking high efficiency and fast turnaround times.

Roll forming machines can produce a wide range of profiles, including C-sections, Z-sections, U-channels, and more. At Bulldog UK, we offer roll formers that are versatile enough to handle different materials, thicknesses, and complex profiles, providing the flexibility to meet diverse production requirements.

With roll formers, you can minimize waste and reduce the need for additional finishing processes, lowering material costs and production time. The ability to produce high volumes of parts in a continuous operation also helps to drive down per-unit costs, making roll forming a highly cost-effective manufacturing method.

At Bulldog UK, we provide an extensive selection of high-quality roll formers tailored to meet various industrial needs. Our machines are built to last, delivering precise results with minimal downtime. Here are some of the key roll forming machines available in our Roll Forming Machines category:

Light gauge roll formers are perfect for creating thin-walled profiles that are commonly used in industries such as HVAC, construction, and electrical enclosures. These machines are ideal for producing metal products like ducts, channels, and frames, with the precision required for such applications.

Designed for producing thicker metal sections, heavy gauge roll formers are used in industries where structural strength is paramount. From steel beams to automotive chassis components, these machines can handle the toughest materials, providing the durability and power required for industrial-grade products.

At Bulldog UK, we understand that every business has unique production needs. That’s why we offer custom roll forming solutions, designed and built to match your specific requirements. Whether you need specialized profiles or high-precision parts, our team can develop bespoke machinery that integrates seamlessly into your production line.

If you're looking for speed without compromising on quality, our high-speed roll formers are the perfect solution. These machines are engineered to handle high-volume production runs while maintaining the highest standards of precision and efficiency. High-speed roll formers are ideal for manufacturers in need of rapid production for products such as metal roofing, siding, or industrial panels.

Our multi-profile roll formers offer unmatched versatility, enabling manufacturers to produce different profiles using the same machine. This reduces the need for multiple machines and allows for quicker transitions between production runs. Multi-profile roll formers are ideal for businesses that manufacture a variety of metal sections and need flexible production capabilities.

Roll formers are used in a wide range of industries to produce metal profiles for a variety of applications, including:

Whatever your industry or specific production needs, Bulldog UK’s roll forming machines provide the accuracy, speed, and durability required to meet the highest standards of quality.

At Bulldog UK, we are dedicated to providing top-of-the-line industrial machinery that helps businesses improve efficiency, reduce costs, and deliver high-quality products. Our team of experts is committed to understanding your unique production needs and offering tailored solutions that maximize your investment.

Here’s why you should choose Bulldog UK for your roll forming needs:

Ready to enhance your production capabilities with Bulldog UK’s roll forming machines? Visit our Roll Forming Machines page to explore the full range of high-performance roll formers we offer.

For more information about our products and services, or to inquire about custom machinery solutions, head over to our website. At Bulldog UK, we are committed to helping you achieve production excellence with innovative machinery solutions.